Benefits that WATER TREATMENT SOLUTIONS Plastic Components Offer

Applications:

- Non Metallic

- Settling Tank

- Rectangular Clarifies

- Non Metallic Components

- Water Reclamation

Advantages:

- Cost Savings

- Self Lubricating

- Weight Reduction

- OEM Replacement Parts

Benefits that Plastic Components Offer

- Noncorrosive

- Self-lubricating

- Low friction

- FDA/USDA approved

- Cost effective

- Abrasion resistant

- Durable

CREATIVE ENGINEERING

From design, to prototyping to process engineering, our experience with the wide range of plastic solutions allows us to solve any plastic component challenge. We also work closely with the leading chain manufacturers in the industry. We visit job sites across the country to review installation methods and to assess our customer’s needs. We’ve even hosted end users at our facility to detail our unique processes and our proven results. We are creative, engineering-minded problem solvers. And it shows.

Custom Fabrication

Diversified Plastics has the skills and equipment to employ a variety of fabrication processes for a variety of materials, from plastics to metals. This enable us to tackle projects that integrate disparate materials and take on complex forms. We can handle single assemblies as well as hundreds of units. We offer a complete range of service from plastic welding to vacuum forming to parts assembly. Our experienced fabricators are cross-trained on all processes and work in the most advanced software interfaces for 3-D fabrication. We employ a variety of advanced equipment and processes in fabricating. We have a vacuum forming machine up to 3’x4’, large ovens up to 5’x12’ for heat forming, and sheet bending equipment up to 10’ long. We also have hot air hand welders, extrusion welders, and hot plate sheet butt welders, and are able to do overlap shiplap welding and spin welding.

INJECTION MOLDING

Injection molding and overmolding is an extremely flexible process that dramatically reduces waste and cost when creating parts especially in mid- to high-volume runs. Large or small, complicated or simple, Diversified Plastics can deliver the molded plastic components you need, on time and on budget. Our process begins at ground zero with in-house design and fabrication of custom tooling and molds, including low-cost aluminum mold inserts. Once we’ve created the molds and completed a test run, we begin full-line production using a variety of materials.

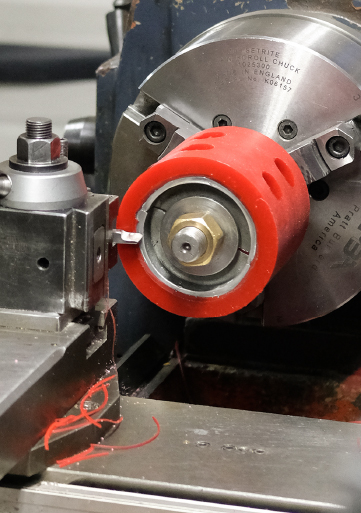

MACHINING

Machining out of solid engineered plastic stock is the ideal way to create parts for applications that require tight tolerances and uniform finish in low- to mid-quantity runs. Inside our 25,000-square-foot facility, you’ll find CNC mills, lathes, and routers, along with precise cutting, drilling, welding, bending, and forming equipment. Machining is ideal for extremely tight tolerances and strict specification requirements.

MULTIFAB TECHNOLOGY™

We combine the capabilities of Fabrication, Machining, Injection Molding, and PolyUrethane Casting under one roof to create an innovative solution for our customer. We call this MultiFab Technology. Our MultiFab capability allows us to create a superior product at a more competitive price and enables one component to be manufactured through several operation processes. MultiFab offers our customers a cost-effective solution when they want to convert to plastic components from metal or other multiple materials.

THERMOFORMING

Forming plastic sheet material with heat and pressure is a very cost-effective and versatile process with low set-up and tooling costs, making it efficient for low volume runs.

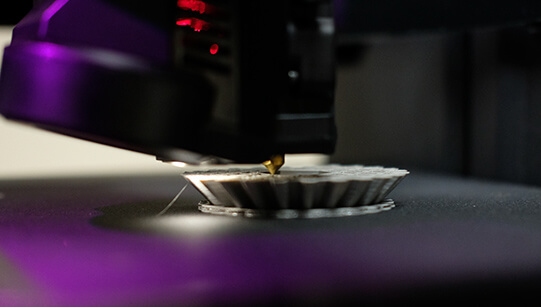

URETHANE CASTING

Pouring liquid urethane into molds and allowing it to cure is a proven method for creating parts in a multitude of shapes, sizes and durometers. Creating urethane components and sheets is entirely different from working with traditional plastics and Diversified Plastics team members use proprietary processes and protocols to maximize the versatility and varying hardness of urethane. Our urethane parts will meet your specifications not only for shape and size, but also for hardness. In fact, we can cast urethane components in durometers from 40A to 75D.

Deer Island Wastewater Treatment

The Project: The Deer Island treatment plant, operated by the Massachusetts Water Resources Authority, is the public wastewater treatment facility for the city of Boston. The plant was undergoing an extensive refurbishment, replacing all of its chain and sprockets. Diversified Plastics, pre-qualified by...

DPI Life

Diversified Plastics Expands Manufacturing in Missoula

New Addition and New Mold Machine Shortens Lead Times In our...

Read More

News

View AllCelebrate the Growth of Manufacturing in Missoula!

October 4, 2023 – Tour times from 3-6 PM, book today! 3721 Grant Creek Rd. Missoula, MT Join us for an exciting new chapter as DPI expands its manufacturing facility in Missoula! Tour the new 50,000-square-foot facility and hear from the team...

Read More

Diversified Plastics, Inc. Receives 2022 Montana Manufacturer of the Year Award

Pictured left to right: Logan Reid (son), Wendy Reid (wife), Brad Reid (President/Owner of DPI), Montana Governor Greg Gianforte with his wife, Susan, Todd O’Hair (President and CEO of the Montana Department of Commerce); and Scott Sehnert (Board Chair, MMA) Missoula, MT – Diversified Plastics, Inc. is...

Read More

Upcoming Events

View AllMINExpo INTERNATIONAL® 2024

MINExpo INTERNATIONAL®, the industry’s largest global mining event, is packed...

View Event

Timber Processing & Energy Expo 2024

Professionals in the lumber, panel, and engineered wood products industry...

View Event

PACK EXPO International 2024

For those needing a solution for every industry and every...

View Event

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!

Give Us A Call

1-800-321-0084

Outside the United States