Egg Processing

These days more and more components on egg processing equipment are being converted over to plastic materials because of the advantages they bring. Take all of your replacement plastic parts requests to Diversified Plastics to learn about the many design improvements we have made to your standard parts, and also learn how we can save you money on OEM replacement parts.

We work with customers all over the world to constantly improve our products from the OEM design, and we are open to implementing your ideas on how to improve your parts to improve your processing efficiencies. All are specifically formulated to prolong wear life and resist chemical attack from your standard cleaning process so when you change over to our replacement parts you can be confident that you are reducing maintenance costs and time.

Products

- Accumulator Table Divider Guides

- Clear Guards

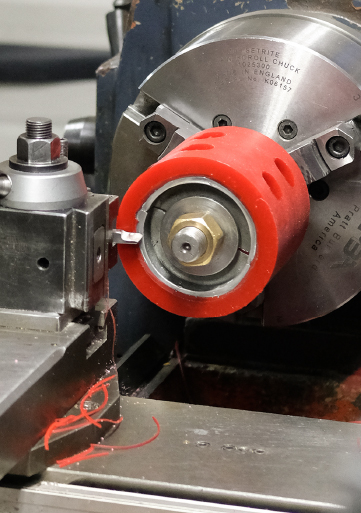

- Belt Idler Rollers

- Idler Sprockets

- Shims

- Conveyor Rollers

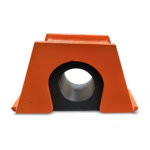

- Washer Bearings

- Shaker Cams

Benefits that Egg Processing Plastic Components Offer

Applications:

- Crack detection

- Wash-down

- Inspection

- Conveying

- Breaking

- Packaging

- Transport

Advantages:

- Cost Savings with Higher Volume Production

- Innovative Engineering to Customize and Improve any Component

- Increase Efficiency

- Reduce Down Time

- Non-Metallic Material

- Prolonged Wear Life

Eggs Come In All Sizes And Styles. As Do Our Engineered Spool Bars

- A variety of FDA materials that deliver high chemical, heat, and wear resistance

- Wide range of Durometers (hardness) can meet all requirements

- Carbon and stainless steel core tubes

- Abrasion resistant nylon end plugs

- Custom molds for non-standard sizes

- Metal detectable plastic resins for injection molded parts