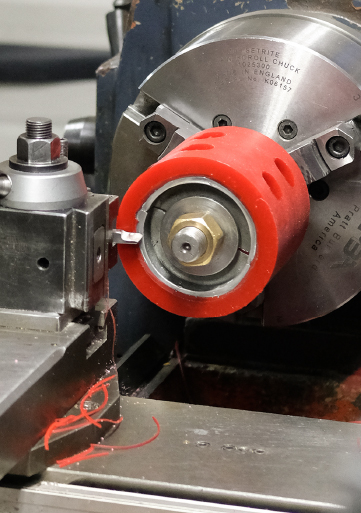

DPI’s Vast Range of Plastic Injection Molding Capabilities Sets Us Apart

Diversified Plastics is an excellent choice for custom injection molded products.

Our range and size of engineered plastic components that DPI can injection mold is nearly limitless in the industrial sector, with our capabilities for molding machine shot sizes ranging from 19 oz. up to 311 oz.

In-house tool design and mold fabrication allows DPI to be a single source supplier for our customers. “We strive to make doing business with DPI seamless, and having all operations under one roof helps us obtain this goal.”

Injection molded UHMW is our specialty – a process not duplicated by anyone else in the world. DPI continuously provides substantial cost savings to customers when converting high cost machined UHMW components to the molded process.

Just some of the materials we use

- UHMW-PE

- Nylon

- Acetal

- Urethane

- Ultem

- PEEK

- HDPE

- Polypropylene

- Glass, carbon, and oil filled.

Mold It or Machine It?

Understanding the molding process and when to utilize it can lead to big cost savings. Low and high volume machined replacement parts are often great candidates for molding instead. The DPI sales and engineering team members have the experience and expertise to help our customers identify and qualify which plastic parts and components are the best candidates to convert from machining to molding. The process includes analyzing geometry, part function, material, and possible design changes to optimize for the molding process.

Mold and Save!

Investing in an injection mold is a short-term investment when compared against long-term savings. Part testimonials in the diagram are just a few examples of five-year savings versus their machined counterparts.

We’re Committed to Finding the Best Solution

Experience creates trust and for over four decades companies globally have trusted DPI to qualify, analyze, and define the most cost effective method of producing their plastic components. If we succeed, our customers succeed and the result is profitable and sustainable growth for all parties. Our model is to be the only source for all your plastic component needs, and to be an industry leader who adds value through innovative ideas, knowledge, and passion to be the best. Additionally, we offer prototyping to test concepts, processes, and materials.

DPI is a leading plastic molding company. Contact us to learn how our team can advise you on the right molding solutions for your engineered/industrial plastic parts applications. Learn more about the benefits of converting to plastics.

Molded Products Sell Sheet

Molded Products Sell Sheet Injection Molding Line Card

Injection Molding Line Card