Blending the best in materials and manufacturing processes to deliver optimum performance.

DPI innovation at work.

To produce truly innovative solutions, our MultiFab Hybrid Design allows us to bring together the right polymers with the capabilities of our fabrication, machining, injection molding, and polyurethane casting departments.

The result is optimum part performance and durability at a competitive price – for any given application.

MultiFab brings it all together for a single, superior part.

We developed our MultiFab Hybrid Design process to address a simple truth: different components of a part often require different qualities for maximum performance.

Get the advantages of DPI MultiFab Hybrid Design:

- Superior Performance – The best materials and production processes optimize the performance of each component.

- Durability and Strength – Integrated design to deliver the best wear life possible.

- Lower Weight – Lighter than cast iron and other materials while still meeting or exceeding specifications.

- Better Pricing – MultiFab approach reduces costs of materials, machining, and waste.

- Customization – Materials and processes optimized for your application.

How MultiFab Hybrid Design gives you the advantage.

Let’s look at a real-world example of how MultiFab makes a difference. Consider that nylon has great tensile strength and is perfect for a drive bore key section of a sprocket; and UHMW makes for excellent wear resistance for teeth and idler bores. However, using just one of these materials to produce an entire part would not deliver the best wear option for the entire part.

With our MultiFab Hybrid Design, we can determine the best material, or multiple materials, for each application. Additionally, with MultiFab, sprocket bores and teeth can be machined, cast, or molded out of the material that is optimal for the part’s design and function. Our MultiFab capabilities allow us to be ahead of the market when it comes to customizing your product for its best service life.

Learn about the range of industrial polymers that we work with to ensure your DPI parts and components are made with the best industrial plastics, polymers, and thermoplastics materials.

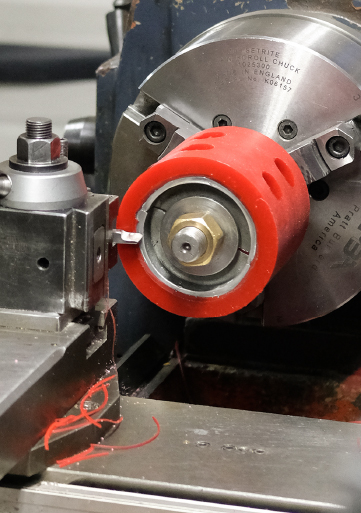

Take a closer look at our MultiFab Hybrid Design process.

Components built using MultiFab Hybrid Design are the result of our custom process that combines the best of proven polymer materials, with up to three fabrication methods, ensuring a superior component design that meets your specifications and addresses the challenge of your application.

Explore the makeup of a component created with DPI’s MultiFab approach:

Intermediate plate and hub is injection molded from high-strength plastic, reducing material waste and maximizing torsion and load-bearing strength.

Intermediate plate and hub is injection molded from high-strength plastic, reducing material waste and maximizing torsion and load-bearing strength.

Center bore and keyway is machined or molded from high-strength nylon, urethane, or glass-filled copolymer to ensure a superior lock to the drive shaft and long keyway life.

Center bore and keyway is machined or molded from high-strength nylon, urethane, or glass-filled copolymer to ensure a superior lock to the drive shaft and long keyway life.

Teeth section is injection molded from a highly abrasion-resistant resin, such as UHMW-PE or urethane, ensuring years of performance and reduced maintenance costs.

Teeth section is injection molded from a highly abrasion-resistant resin, such as UHMW-PE or urethane, ensuring years of performance and reduced maintenance costs.

According to independent lab reports, DPI’s MultiFab sprockets are stronger and wear better than sprockets made of a single material.

Our MultiFab approach is cost effective, produces less material waste, and is a great way to update and convert your metal parts to plastic solutions.

Our MultiFab capabilities and design engineering, all under the same roof, allow us to customize your plastics components for their best wear life.

Developing solutions to your challenges.

By using all our diverse capabilities and materials, our engineering and sales teams are experts at finding solutions to your challenges that others miss.

From improving design and increasing wear life to eliminating unnecessary components or production processes and reducing costs, the best way to optimize your parts and components is to have DPI assess the materials, design, and process. Contact us to learn more about how DPI can develop your MultiFab Hybrid Design solutions, all under one roof.

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!

Give Us A Call

1-800-321-0084

Outside the United States