Plastic Innovators

Custom Design, Engineering, and Manufacturing

Let's Solve It

The impact that a new plastic part can have on the big picture might surprise you. So don’t hesitate to share your challenges with DPI. We’ll listen, collaborate, and find the solution. Whether you want to cut costs, increase lifespans, reduce breakdowns, test the performance of polymers, or explore a custom part idea, we’ve got your back.

- Custom Fabrication

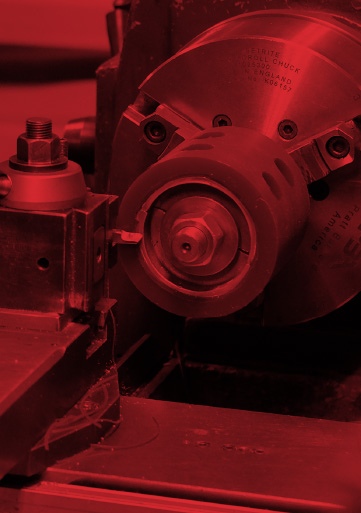

- Machining

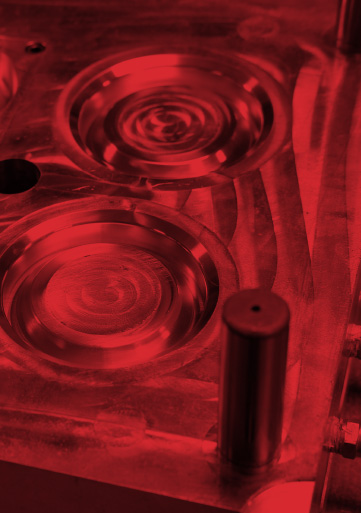

- Injection Molding

- Injection Molding UHMW-PE

- Urethane Casting

- Thermoforming

- Plastics Welding

- Vacuum Forming

- Overmolding of Steel Parts

- QC Testing

- Stamping, Labeling Parts ID

- MultiFab Hybrid Components™ Solutions

Anything is Possible with DPI as Your Partner

No matter your part, material, application, or industry, we’ll find the best solution for your situation

A Visit to Your Site

Let’s arrange a meeting at your facility for a full evaluation at no cost to you.

With an assessment of your processes, materials, designs, and parts we can almost guarantee we will find a solution to help.

Contact Us

"*" indicates required fields

Case Studies

Upcoming EventsView All

Seafood Expo North America 2026

March 15–17, 2026 | Attending

Learn MoreEXPO Richmond (East Coast Sawmill and Logging Equipment Exposition)

April 17-18, 2026 | Attending

Learn MoreTimber Processing and Energy Expo (TP&EE)

September 23-25, 2026 | Exhibitor

Learn MoreHighlightsView All

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!