The Client Challenge

Spectrum Products was sourcing multiple parts and components from multiple sources. While it was getting quality products, the process was inefficient and expensive — especially on some of its short-run products — which cut into its profit margin. A Diversified Plastics sales specialist called on the OEM customer and walked through our variety of fabrication processes.

The Diversified Plastics Solution

The Diversified Plastics Solution

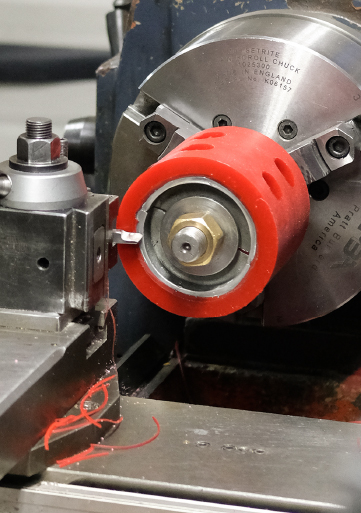

Results – Parts were injection molded, machined, cast out of urethane, and also, vacuum formed. Diversified Plastics combined processes when necessary. We also machined low-volume prototypes, then converted to injection molding at a later date, including custom coloring and logos for larger production runs.