DPI is the Only Source for Injection Molded UHMW Plastic Parts, Providing Unparalleled Benefits of Wear Resistance, Corrosion and Chemical Resistance, and Low Friction

DPI’s Injection Molded UHMW-PE (Ultra-High Molecular Weight Polyethylene) is an excellent material choice for parts and components that require structural strength, low friction, lubricity, abrasion resistance, and corrosion resistance. It is an extremely durable, yet lightweight, engineered plastic material. Because of its unique molecular/structural properties, UHMW-PE provides benefits that make it superior to any other plastic as well as metals – in fact UHMW-PE is an excellent metal alternative in many applications.

Injection-moldable UHMW-PE resin is an extraordinarily versatile material suited to thousands of industrial applications.

Injection molding reduces time and costs relative to machined plastic components. It allows for production options such as over-molding on other materials, bonding with elastomers, and even molding around threaded metal inserts or objects. It makes it easy to mold-in valuable information such as company names and logos, part numbers, custom colors, and manufacturing dates.

We’re changing the plastics game with molded UHMW

Learn our secret to your industry success.

Contact a sales rep today!Or call us at 1-800-321-0084

UHMW Advantages

- Wear Resistant

- Injection Moldable Proprietary UHMW Resin*

- Extremely Tough and Durable

- Faster Cycle Times Versus Machining

- Lightweight and Versatile

- Corrosion Resistant

- Impact Resistant

- Lubricity/Self-Lubricating

- Noise Level Reduction

- Easily to Work With

- Machinable Plastic

- Less Expensive Per Pound Compared to Rod/Sheet

- High/Low Production Runs

- Reduced Material Waste/Cost Efficient

- OEM Replacement Parts

*DPI manufactures its own proprietary UHMW Resin to create the only injection moldable UHMW-PE on the market.

Common molded UHMW-PE Products

- UHMW Sprockets

- UHMW Gears

- UHMW Wear Strips

- UHMW Drive Components

- UHMW Diverter Arms/Guards

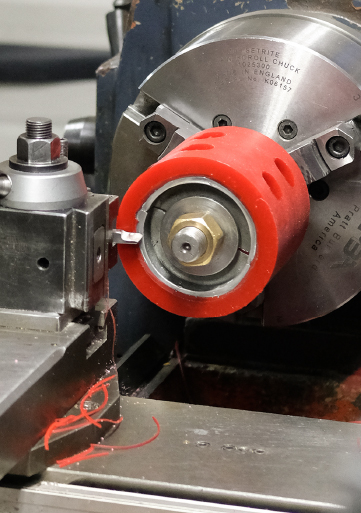

- UHMW Wheels & Rollers

- UHMW Bearings & Bushings

- UHMW Guards & Bumpers

- UHMW Pulleys & Belt Sheaves

- OEM Replacement Parts

Injection Molded UHMW-PE Only from DPI

DPI is the only manufacturer with the capability to injection-mold UHMW-PE thanks to our state-of-the-art facilities, plastics expertise, and most importantly our proprietary injection molding process. Our custom injection molding capabilities provide benefits such as custom and precision parts work, faster cycle times, reduced material waste, cost efficiencies, and high production runs. So, why machine it when you can mold it?

Many industries are discovering the benefits of UHMW-PE for essential equipment. Our team of engineers works with sales to help you to develop the right UHMW structure to suit the unique demands of your specific application. DPI is a custom UHMW injection molding company. Learn more about the industries we serve.

Injection Molded UHMW Resin Compound

Injection Molded UHMW Resin Compound Molded Products Sell Sheet

Molded Products Sell Sheet