Our creative, design engineering team can help you reimagine and elevate parts for current and future applications.

On-site engineering expertise.

We approach plastic engineering with creativity, determination, and a progressive mindset. Our engineering department includes engineers from a range of disciplines, each bringing their unique expertise and playing a key role in areas of design, materials, manufacturing and production, automation, and quality assurance – all under one roof.

Engineering ideas into solutions.

Our approach to design engineering starts by gaining an understanding of your part needs or application challenges.

For example:

- How is the part used?

- What environment or conditions will the part be subjected to?

- How can we help lower your part costs?

- What advantages will engineered plastic parts offer over metal parts?

- What type of plastic materials will keep the part performing best in the long run?

Our engineers will begin a conceptual design phase to explore part designs and new ideas, including modeling with CAD and solid modeling software. Throughout the creative engineering process, we’ll also consider factors like manufacturing processes and production efficiencies. Next, we’ll move on to prototyping, manufacturing, testing, and quality assurance steps – ultimately delivering the final innovative solution.

A collaborative approach

The DPI team includes engineers offering a range of areas of expertise. We can also work in collaboration to support your engineers and technicians, bringing our unique experience and plastics materials expertise to help achieve your objectives. It’s about providing you with better solutions and helping you get to where you want to be.

Innovation based on industry insights.

DPI engineers are at the forefront of plastic innovation. Our ideas are based on engineering expertise and keeping up with the latest advancement in polymers and industry needs. For example, we work closely with leading OEMs and manufacturers to understand specific manufacturing, procurement, and maintenance concerns. And we visit customers and job sites across the country to review installation methods and assess real world needs.

Explore our case studies to see how we’re revolutionizing plastic solutions for our clients in a wide range of industries.

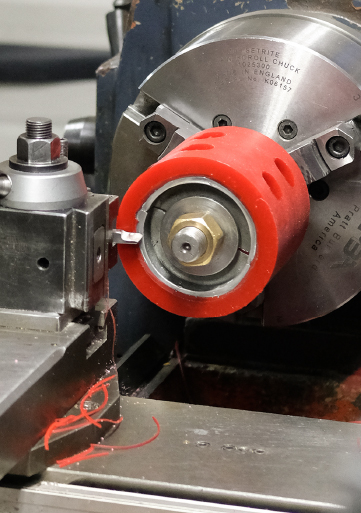

In-house tooling for efficient prototyping and production.

Our engineering capabilities include having access to our own tooling and software/programming solutions to support unique design and production needs.

With in-house tooling we can more efficiently develop your custom engineered plastic parts or components thanks to the ability to directly communicate project details, provide rapid prototypes, and assure quality at every step. And that can mean a shorter time frame to the production and implementation of your newly engineered plastic parts and components.

Quality assurance at every step.

To ensure the products we produce meet or exceed superior standards and are without defects, we implement a range of measures throughout our engineering and production process. We also develop individualized Quality Assurance (QA) plans to meet customers’ specific product QA or compliance needs.

DPI’S quality assurance steps include:

- Ongoing testing

- Monitoring the manufacturing process

- First and last article checks for each operation

- Continually testing and calibrating our equipment

- Maintaining ISO compliance

Our quality assurance mission

Championing superior quality work – working closely with all departments to test and release final products to our customers.

We are also committed to raising the standards of excellence by not only teaching process improvements but also seeking ways to enhance and refine DPI systems and operations.

Explore the possibilities with plastic.

Today’s industrial plastics offer many advantages over metal materials like stainless steel and bronze. In fact, you might be surprised at the range of metal parts that can be replaced with industrial plastic. Through our engineering expertise and extensive experience, combined with the wide range of plastic components and solutions – including injection-molded UHMW – we can solve any challenge.

If you’re currently working with metal parts, it’s time to consider your engineered plastics options and see the benefits of making the switch to plastic.

Let’s get started.

We welcome your engineering challenge – from developing new parts and designing custom components to resolving problem parts or exploring cost reductions and production increases. DPI will help you find a creative-engineered, plastic-based solution.

Contact us about collaborating with our team of design engineers and problem solvers on innovative plastic parts solutions for your application.

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!

Give Us A Call

1-800-321-0084

Outside the United States