Why Plastics?

Plastics have come a long way, progressing into the top material solution for engineers, servicing a wide range of industries. Their material composition allows design-engineering innovation to be limitless. Plastics provide flexibility, quality options, and a superior product to meet demanding application needs. The beneficial characteristics of plastics include: light weight; high chemical and corrosion resistance; a low coefficient of friction; abrasion resistance, ease of fabrication, machining, molding and casting; reduced cost; and eco-friendly.

Light Weight

The weight of plastics is fairly low, especially compared to alternatives such as metals, wood, and glass. For example, if a part is stainless steel with a weight of 8 pounds, that same volume in nylon would only weight 1 pound. A lighter product means easier transportation and more economical shipping costs.

Chemical and Corrosion Resistance

It’s almost difficult to think of materials such as cast iron, bronze, steel and copper without corrosion coming to mind. Corrosion is not only a detriment, it can also be dangerous and prevented with the use of plastics. Water is the major cause of corrosion, yet plastics do not corrode in aquatic applications. Although plastics are not impervious to chemicals and temperature, you can choose a plastic that will excel in your specific chemical and temperature environment based on your specific chemical composition and required operating temperature.

Low Coefficient of Friction

Another positive characteristic of plastics is its low coefficient of friction. Why does this matter? Having a low coefficient of friction saves the designer time, money, and unnecessary effort. For example, instead of expensive sealed bearings in corrosive environments, you can use nylon bearings that are proven to last longer and don’t require constant lube maintenance.

Abrasion Resistance

UHMW Polyethylene, Acetal, Nylon, Polyurethane and PEEK are excellent in abrasive environments, and can outwear steel in sliding applications. Using plastics increases part longevity and maximizes efficiency.

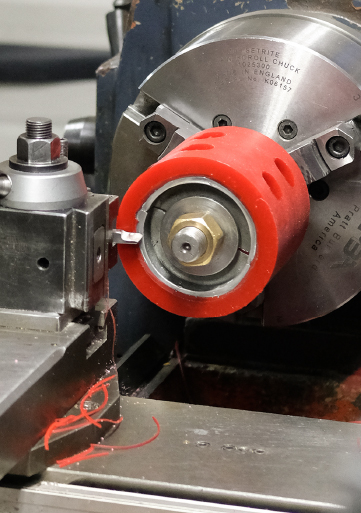

Ease of Fabrication, Machining, Molding and Casting

Although plastics have proven to be tough and durable, their production processes are quite the opposite. The fabrication, machining, molding, and casting of plastics are easier than metals, wood, and glass. Plastics can be machined with common metal and wood techniques such as sawing, routing, and drilling. They can be joined by gluing or welding, and fastened by screws or rivets. Additionally, thermoplastics can be thermoformed into totally new shapes and many plastics can be injection molded.

Reduced Cost & Eco Friendly

Aside from the engineering processes, plastics are also the superior solution for the simple fact that non-metallic materials are more economical and better for the environment. Plastics cost less to manufacture and take less energy to produce than stainless steel, aluminum, and brass. Furthermore, most thermoplastics can be recycled and are often made using recycled internal trim and sheet remnants. It’s quite simple, plastics are the most cost-effective eco-friendly choice. With a variety of processes including: fabrication, injection molding, machining, urethane casting, and thermoforming, there are unlimited ways to utilize plastics in your industry.

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!

Give Us A Call

1-800-321-0084

Outside the United States