Celebrate the Growth of Manufacturing in Missoula!

October 4, 2023 – Tour times from 3-6 PM, book today! 3721 Grant Creek Rd. Missoula, MT Join us for an exciting new chapter as DPI expands...

Creators Wanted!

Creators Wanted! Are you considering a career in manufacturing? You will be able to find work! Learn more about the workforce from The National Association of Manufacturers and The...

Diversified Plastics, Inc. President and Owner To Be Keynote Speaker at Missoula Manufacturing Day

Missoula, MT – Diversified Plastics, Inc. President and Owner, Brad Reid, will be the Keynote Speaker at the 2022 Missoula Manufacturing Day. The Missoula Manufacturing Day highlights the career potential...

Diversified Plastics, Inc. Receives 2022 Montana Manufacturer of the Year Award

Pictured left to right: Logan Reid (son), Wendy Reid (wife), Brad Reid (President/Owner of DPI), Montana Governor Greg Gianforte with his wife, Susan, Todd O’Hair (President and CEO of the Montana...

Diversified Plastics, Inc. Updates Website and Moves to a .Com Address

Diversified Plastics, Inc., a North American leader in plastics engineering and fabrication, has recently updated their website and moved the address to dpiplastics.com. In addition to offering easy-to-access information and...

Diversified Plastics, Inc., continues to contribute time, energy, resources, and goodwill to the Missoula community.

Staff and visitors at the Missoula Food Bank and Community Center can feel a little safer from the potential spread of CORVID-19, thanks to the generosity of DPI and its President/Owner Brad...

Expanding Our Facility, Creating More Jobs

Diversified Plastics, Inc. was recently awarded a grant from the Montana Department of Commerce - Big Sky Economic Development Trust Fund (BSTF) Program. The money awarded will assist DPI with...

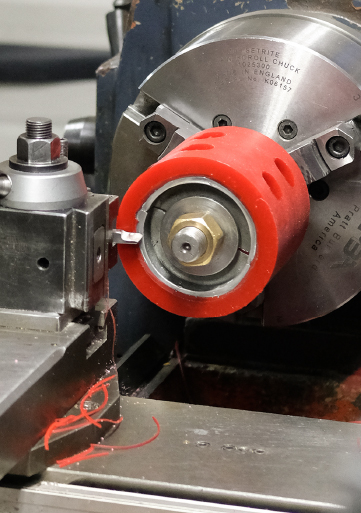

Food Processing: Metal Detectable Plastic Components

Reduce Wear, Maintenance and Contamination Risk Food processors and other industries use metal detectors to identify contamination from a variety of sources, including fragments from machinery and parts. Detecting such contamination...

Helping our state is our pleasure

In the midst of the global COVID-19 pandemic, Diversified Plastics, Inc., has stepped forward to be a good neighbor to our fellow Montanans. We pivoted production to produce plastic molded...

Lee Enterprises Names Diversified Plastics, INC. a Winner of the Montana Top Workplaces 2021 Award

Missoula, Montana July 25, 2021 - Diversifed Plastics, Inc. has been awarded a Top Workplaces 2021 honor by The Montana Top Workplaces. The list is based solely on employee feedback...

Missoula’s Diversified Plastics, Inc. to Receive 2020 Exporter of the Year Award

The Montana District Export Council, of which the Department of Commerce is a member, will award the Missoula-based manufacturing business Diversified Plastics, Inc., its 2020 Exporter of the Year award. “Diversified...

Montana World Trade Center

Thank you to the Montana World Trade Center for highlighting our own Diversified Plastics, Inc. We are proud to be members of this organization that brings together trade centers from...

Montana World Trade Center Member

Diversified Plastics is honored to be the Montana World Trade Center's (MWTC) Featured Member. Through the years, our membership in the Montana World Trade Center has allowed us the benefit of...