Reduce Wear, Maintenance and Contamination Risk

Food processors and other industries use metal detectors to identify contamination from a variety of sources, including fragments from machinery and parts. Detecting such contamination before it leaves the plant greatly reduces liability and prevents massive recalls. In the past, that need forced processors to use metal components where plastic ones might actually wear and function better. Not any more. Diversified Plastics is pleased to introduce truly Metal Detectable Plastic Components.

Our innovative, tested process combines special additives with polymer resins to produce metal and X-Ray detectable injection molded components that are FDA approved. By incorporating these additives at precisely the right ratios, components can be easily identified by standard metal detectors and X-ray machines. Moreover, combined with proper material selection, our process actually improves wear and slide properties of components.

Features and Benefits

-

- Small particles detected by standard equipment at sizes less than 1 mm in diameter.

- Reduces liability by reducing the likelihood of contamination.

- Reduces wear, weight and noise compared with metal components.

- Available in a wide range of polymers and elastomers to suit any application.

- FDA approved for food contact applications.

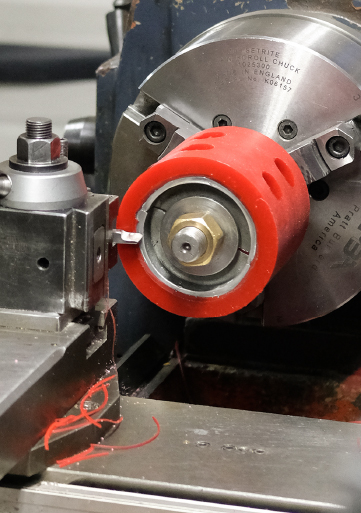

- Standard resin colors are black and gray. Pigments such as red, blue, green and orange can be added.