Plastic Components for Mining Equipment

Proven Plastic Components for Harsh Mining Conditions

Request a Quote1-800-321-0084

Trusted Plastic Component Solutions for the Mining Industry

For decades, Diversified Plastics Inc. has worked with industry-leading OEMs and distributors to develop long-lasting plastic components for mining equipment. When it comes to harsh conditions and the need for durable plastic components, mining is at the top of the list. Our engineered plastic solutions are designed to withstand the demanding environments of mining filtration equipment and conveying systems.

Mining Equipment Applications

- Filtration

- Separation

- Process Equipment

- Conveying Systems

- Disc Filter Equipment

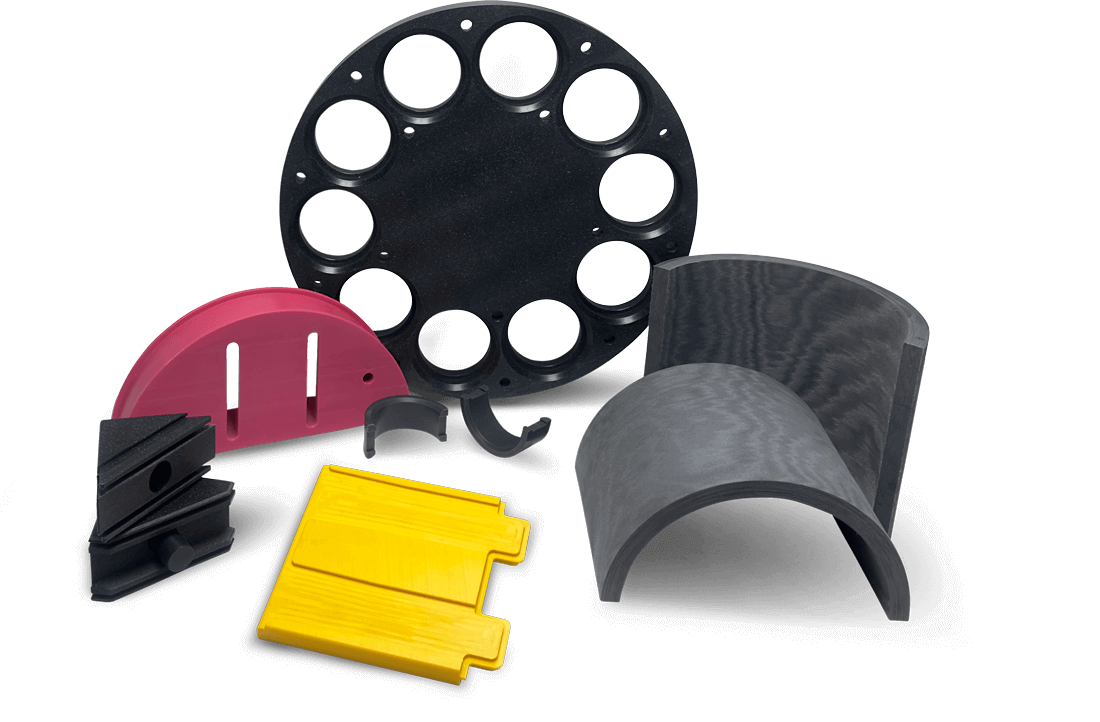

Engineered Plastic Components and Parts

- Filtration System Parts

- Conveyor Components

- Separation Equipment Parts

- Process Equipment Components

What Plastic Components Are Used in Mining Equipment?

We provide custom plastic components for mining filtration, separation, process equipment, and conveying systems. Our parts fit a variety of applications in the mining industry from OEMs to end users, delivering solutions that span the entire mining operation.

From engineering and testing to final production, DPI uses decades of experience to help specify the right material for the application. We offer versatility when it comes to material selection and manufacturing processes, providing economical options utilizing our full range of capabilities all under one roof.

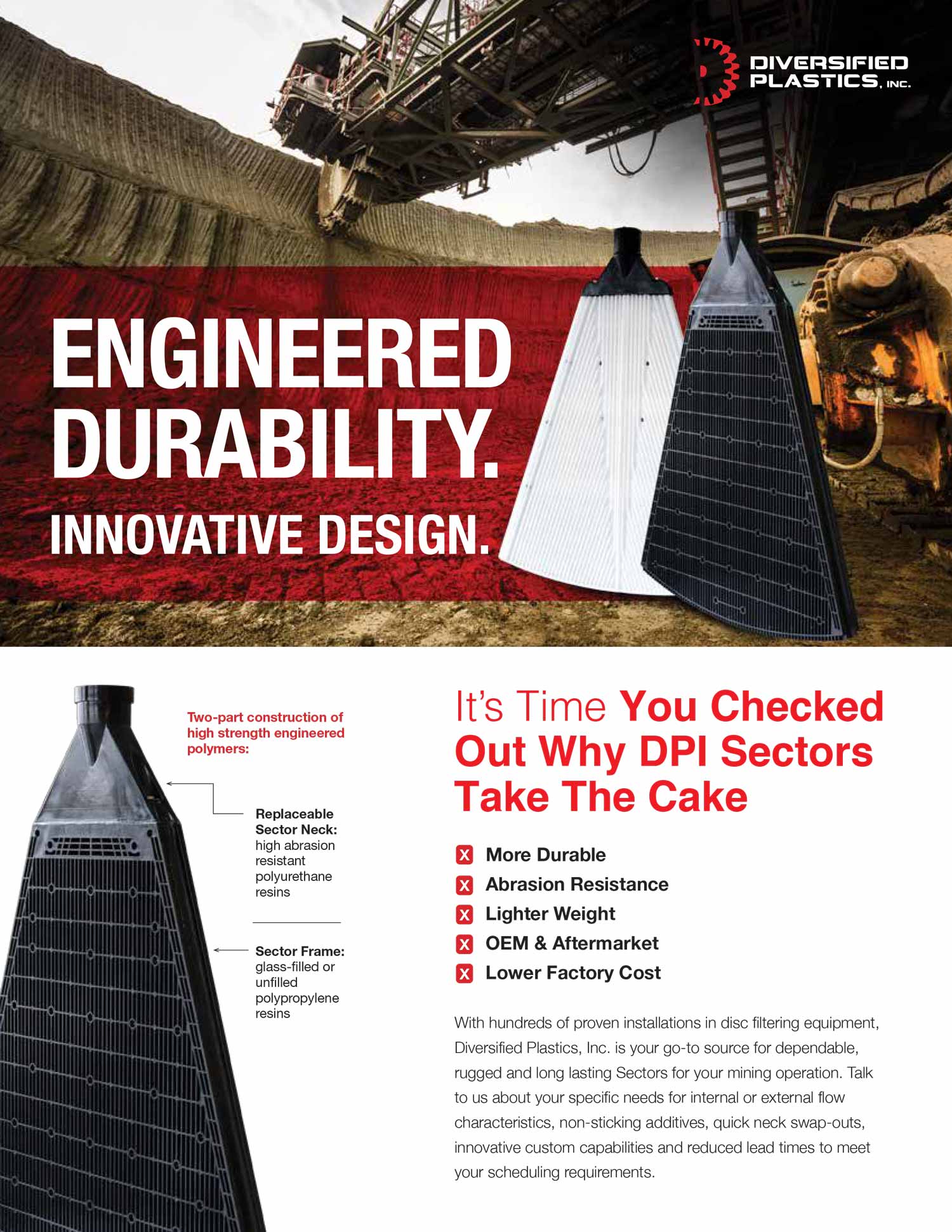

Disc Filter Sectors

DPI Sectors are our flagship mining product, with hundreds of proven installations in disc filtering equipment worldwide. These Sectors have been subjected to stringent field testing and are proven in use across many mining operations.

Sector Features and Benefits:

- Available for both OEM and aftermarket applications

- Come in a variety of custom sizes

- Easily removable and replaceable necks for routine maintenance or unexpected downtime

- Interchangeable with most common disc filter sizes and bag sizes

- Smooth edges to extend bag wear

- Non-stick polymer additives available to minimize internal cake buildup

- Lighter weight for easier shipping, handling, installation, and maintenance

What Are the Benefits of Plastic Components vs. Metal Parts?

For mining operations, DPI’s engineered plastic and polymer products offer a range of important advantages over traditional materials. Our plastic components outlast and outperform the competition in wear and durability.

Key Advantages of Plastic Components

- Highly Durable

- Cost Effective

- Abrasion Resistant

- Corrosion Resistant

- Chemical Resistant

- Self Lubricating

- Impact Resistant

- Lighter Weight

- Lower Factory Cost

- OEM & Aftermarket Solutions

The exact plastic material composition is an important factor when specifying parts for equipment used in the mining industry. Our plastic experts will determine the best plastic material, including custom resins and colors, for your application.

Material Selection Expertise

From engineering and testing to final production, we use decades of experience to help specify the right material for your mining application. We offer endless versatility when it comes to material selection and can provide the most economical option for your specific needs.

Custom Capabilities

DPI has the capability of manufacturing a variety of custom sizes and configurations. We can accommodate specific needs for internal or external flow characteristics, non-sticking additives, quick neck swap-outs, and innovative custom capabilities with reduced lead times to meet your scheduling requirements.

Why Choose Diversified Plastics for Mining Equipment Parts

We know that mining operations call for durable, wear- and impact-resistant plastic components that can withstand the most demanding conditions. No matter what your operation requires, you can depend on Diversified Plastics OEM and replacement parts to keep up with your needs for the best value and performance.

The mining industry has recognized our components for their durability, performance, and economic advantage. With hundreds of proven installations, our products have demonstrated superior wear resistance and longevity in the field.

Thousands of DPI components have been subjected to the most stringent field testing and are proven in use across many mining operations. Let us work with you on your disc filter standard or custom component needs. You’ll find our service is as responsive as our products are durable.

Contact DPI for Mining Equipment Plastic Parts Expertise

From design to prototyping to process engineering, our team’s experience and expertise with the wide range of plastic solutions allows us to solve any plastic component challenge. Learn how we can put polymers to work for you!

Contact the sales experts at DPI to discuss your mining equipment part needs, problem parts, weight reduction objectives, or custom part needs.

Call us today: 1-800-321-0084

Talk to us about your specific requirements and discover how DPI plastic components can improve your mining operation’s efficiency and reduce downtime.

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!