The Project:

The Deer Island treatment plant, operated by the Massachusetts Water Resources Authority, is the public wastewater treatment facility for the city of Boston. The plant was undergoing an extensive refurbishment, replacing all of its chain and sprockets. Diversified Plastics, pre-qualified by the independent design engineering firm, earned the award of an equipment order. By the end of the one-year contract, more than 4,600 SS715C23T sprockets for head shafts and corner shafts will have been delivered, as well as all the polyurethane NH78-40T sectional teeth that were molded for the 575 offset hubs included in the job.

The Deer Island treatment plant, operated by the Massachusetts Water Resources Authority, is the public wastewater treatment facility for the city of Boston. The plant was undergoing an extensive refurbishment, replacing all of its chain and sprockets. Diversified Plastics, pre-qualified by the independent design engineering firm, earned the award of an equipment order. By the end of the one-year contract, more than 4,600 SS715C23T sprockets for head shafts and corner shafts will have been delivered, as well as all the polyurethane NH78-40T sectional teeth that were molded for the 575 offset hubs included in the job.

The Client Challenge:

Engineering specifications called for sprockets to be either cast or injection molded from 70D-75D polyurethane. Diversified Plastics offers both processing capabilities and bid both options. The challenge came in providing the part at the right price and on time. Diversified Plastics’ goal was to meet or exceed specs at a price point well within budget, as well as to maintain a stringent delivery schedule.

Engineering specifications called for sprockets to be either cast or injection molded from 70D-75D polyurethane. Diversified Plastics offers both processing capabilities and bid both options. The challenge came in providing the part at the right price and on time. Diversified Plastics’ goal was to meet or exceed specs at a price point well within budget, as well as to maintain a stringent delivery schedule.

There were extensive evaluations completed of both manufacturing processes to determine the best fit. Engineers and contractors from the Boston site visited the Diversified Plastics plant in Missoula and worked closely to ensure the process selected would produce the desired product. Prototypes were tested extensively, both in-house and by an independent laboratory located in Chicago.

The Diversified Plastics Solution:

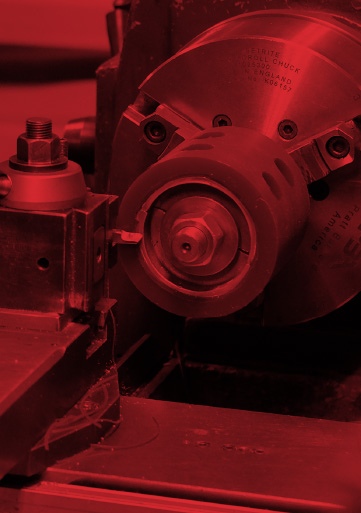

Injection molding became the clear choice for manufacturing. The process reduces material waste and is less labor intensive, which ensures the desired product can be delivered on time and on budget. For thermoplastic polyurethane, we worked closely with BASF and ultimately chose the best material to meet specified requirements — including a high tensile strength (for carrying the load) and a high wear property (for long-lasting wear).

Injection molding became the clear choice for manufacturing. The process reduces material waste and is less labor intensive, which ensures the desired product can be delivered on time and on budget. For thermoplastic polyurethane, we worked closely with BASF and ultimately chose the best material to meet specified requirements — including a high tensile strength (for carrying the load) and a high wear property (for long-lasting wear).

Diversified Plastics engineered the process to mold the sprockets in a fashion that met all the project requirements. This process also helped reduce time, material and waste, and assisted in meeting the stringent delivery schedule. The necessary dies were all tooled by us, in-house, for projects such as this.

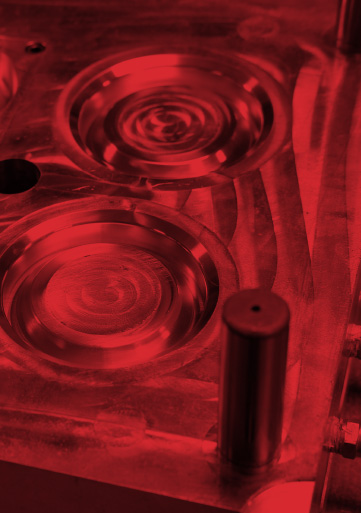

The finished piece was a large 23.3-inch OD sprocket with chain saver rim and 6-inch LTB. Its finished weight was 33 pounds. It exceeded the specifications and reduced long-term maintenance costs at Deer Island. The sprocket readily carries the 2,200-pound max chain load required. It was both abrasion resistant to withstand the high grit slurry and corrosion resistant against the harsh chemicals.

In independent testing, the sprocket was submerged and run in a simulated, abrasive chemical tank. It showed miniscule teeth-wear after the accelerated five-year test and was still running strong after the accelerated 15-year mark. To ensure consistency and quality control throughout the entire run, Diversified Plastics thoroughly tested the products in-house, including a 4,500-pound, static load test on every hundredth part produced.

The Massachusetts Water Resources Authority completed installation of the sprockets and was pleased with how easily the sprockets installed.