Wastewater Treatment Solutions

Proven Plastic Components for Industrial Wastewater and Water Treatment Facilities

Request a Quote1-800-321-0084

Trusted Plastic Component Solutions for the Water Treatment Industry

Diversified Plastics Inc. has been serving the water treatment industry with quality, engineered plastic components for over a decade. Many treatment facilities are moving away from metal and toward plastic components because they outlast and outperform metal parts. Our MultiFab™ water treatment sprockets and UHMW components have revolutionized the wastewater industry by combining materials to lower cost, reduce weight, and extend sprocket component life. hi

Water Treatment Equipment Applications

- Bar Screen Components

- Grit Collector Components

- Rectangular Clarifiers

- Circular Clarifiers

- Rectangular Sludge Collectors

Engineered Plastic Components and Parts

- Grit Collector Conversion Parts

- Sprockets

- Grit Collector Buckets

- Return Rail Wearstrips

- Chains

- Drag Flights

- Carry Rail Wearstrips

- Wear Shoes

- Bar Screen Conversion Parts

- Sprockets

- Chains

- Rakes

- Rectangular Sludge Collectors

- Drive Chains

- Shear Pin Assemblies

- Sprockets

- Wall Bearings

- Wall Brackets

- Collector Chains

- Wearstrips

- Flights

- Flight Blocks

- Wear Shoes

What Plastic Components Are Used in Water Treatment Equipment?

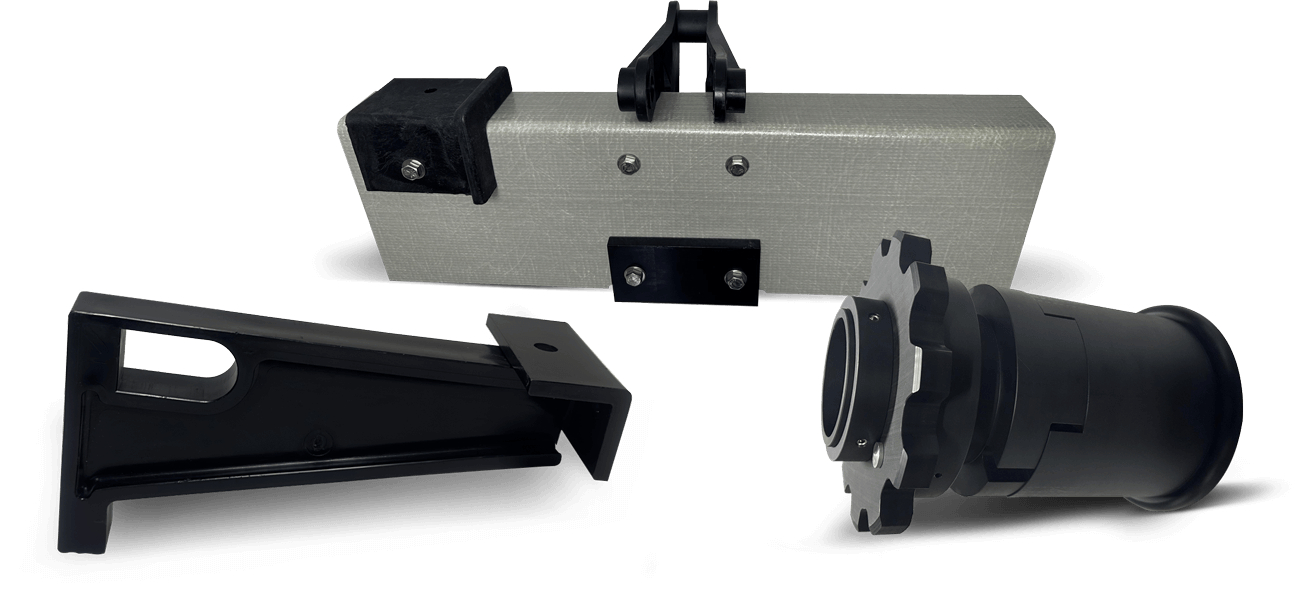

We provide custom plastic components for industrial wastewater treatment facilities, municipal water treatment plants, and water processing operations. Our parts fit a variety of applications in the water treatment industry from OEMs to end users, delivering solutions that span the entire treatment process.

From initial screening and collection to clarification and sludge processing, we see to it that water treatment operations run as smoothly and cost-effectively as possible, helping to minimize maintenance or downtime. We develop, engineer, and produce an extensive line of plastic components for wastewater and water treatment equipment.

As a single source for plastic parts engineering, tooling, and production, we can accommodate a range of project needs. Whether you require custom orders, short production runs, or high-volume quantities, our multiple manufacturing processes are designed to meet your specifications.

How to Choose the Right Plastic Material for Water Treatment Equipment Parts

The exact plastic material composition is an important factor when specifying parts for equipment used in the water treatment industry. Our plastic experts will determine the best plastic material, including custom resins and colors, for your application.

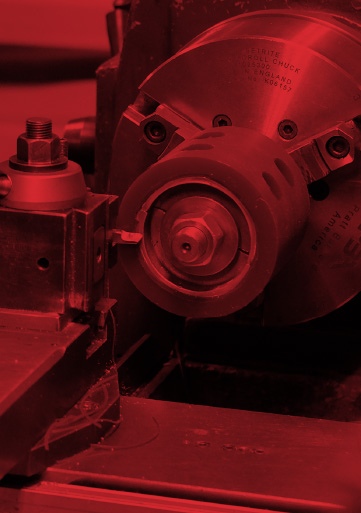

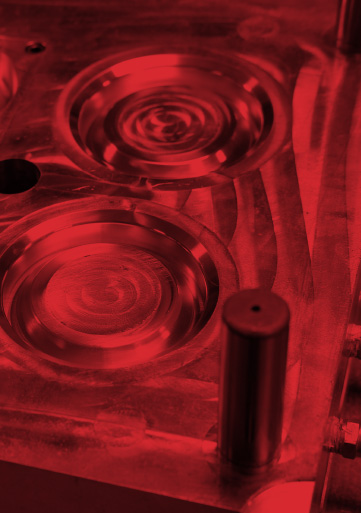

DPI’s UHMW (ultra high molecular weight) polyethylene is an excellent material choice for parts and components used in water treatment equipment applications that require superior durability, wear resistance, low friction, and corrosion resistance. Additionally, UHMW plastic can be machined, fabricated, or injection molded.

Our proprietary MultiFab water treatment sprockets combine optimal polymers with the most efficient process to produce the best, most durable product at a lower cost, with higher strength, reduced weight, and extended sprocket life. DPI’s customized water treatment sprockets and many plastic components are abrasive, chemical, and corrosion resistant while withstanding the high humidity, continual submersion, and high pressure of industrial wastewater and water treatment applications.

For industrial wastewater treatment facilities and water treatment plants, DPI’s engineered plastic and polymer products offer a range of significant advantages over traditional materials:

Key Advantages of Plastic Components

- Self Lubricating

- Wear Resistant

- Corrosion Resistant

- Cost Savings

- Light Weight

- Chemical Resistant

- Abrasion Resistant

- Withstands High Humidity

- Continual Submersion Capability

- High Pressure Resistance

- OEM Replacement Parts

Why Choose Diversified Plastics for Water Treatment Equipment Parts

We know that wastewater treatment, water processing, and industrial water treatment require durable, wear- and corrosion-resistant plastic components. No matter what your company requires, you can depend on Diversified Plastics OEM and replacement parts to keep up with your operation’s needs for the best value and water quality.

Diversified Plastics leads the industry with cost-effective, sound applications in the water treatment industry. With our many capabilities, we strive to resolve problems that hinder production and efficiency. We know our customers’ need for reliable solutions, and our plastic sprockets, when compared to traditional steel sprockets, provide the long-wear performance you need in production.

To keep your water treatment equipment operating efficiently, consider DPI your best source for essential plastic parts to support your preventive maintenance program and replacement parts inventory. For emergency repairs or parts replacement, our team is standing by to provide the parts you need to minimize production downtime.

Contact DPI for Water Treatment Plastic Parts Expertise

From design to prototyping to process engineering, our team’s experience and expertise with a wide range of plastic solutions allow us to solve any plastic component challenge. Learn how we can put polymers to work for you!

Contact the sales experts at DPI to discuss your water treatment equipment part needs, problem parts, weight-reduction objectives, or custom parts.

Call us today: 1-800-321-0084

The use of plastic is endless in the water treatment and wastewater industry. Call Diversified Plastics today to find out how we can improve your production.

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!