Plastic Components for Sawmills, Lumber Mills and Forest Equipment

Proven Plastic Components for High-Performance Cutting, Sorting, and Conveying Machines

Request a Quote1-800-321-0084

Trusted Plastic Component Solutions for the Forest and Lumber Industry

Diversified Plastics Inc. has been serving the forest and lumber industry with quality, engineered plastic components for equipment repair and maintenance for nearly 50 years. We provide custom plastic components for sawmills, paper mills, pulp mills, and other timber producers.

No matter how you cut it, our plastic parts will help you finish it.

From intake and rough sorting to loading and delivery, we see to it that timber processing operations run as smoothly and cost-effectively as possible, helping to minimize maintenance or downtime.

Lumber Processing Equipment Applications

- Sawmill Infeed

- Debarkers

- Trimmers

- Graders

- Dry Kilns

- Planers

- Stackers

- Bin Sorters

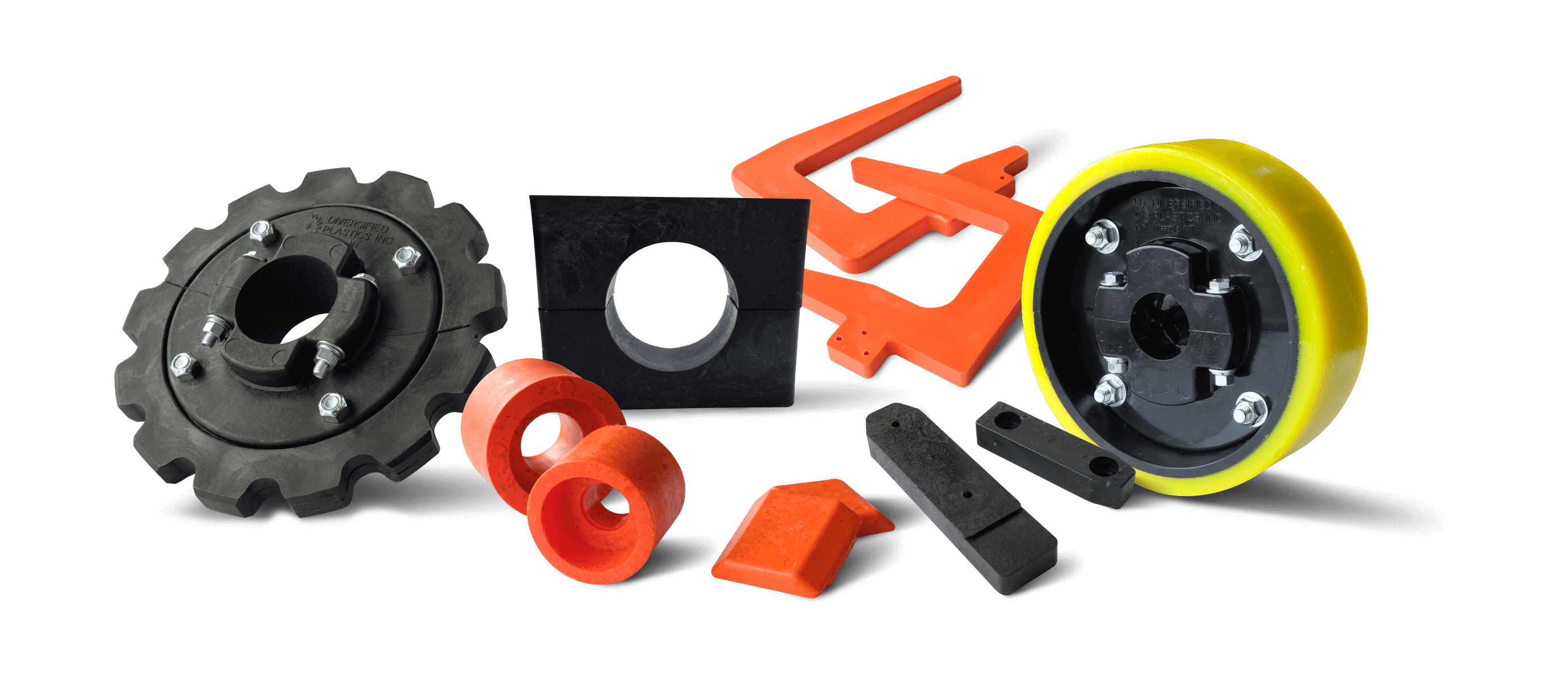

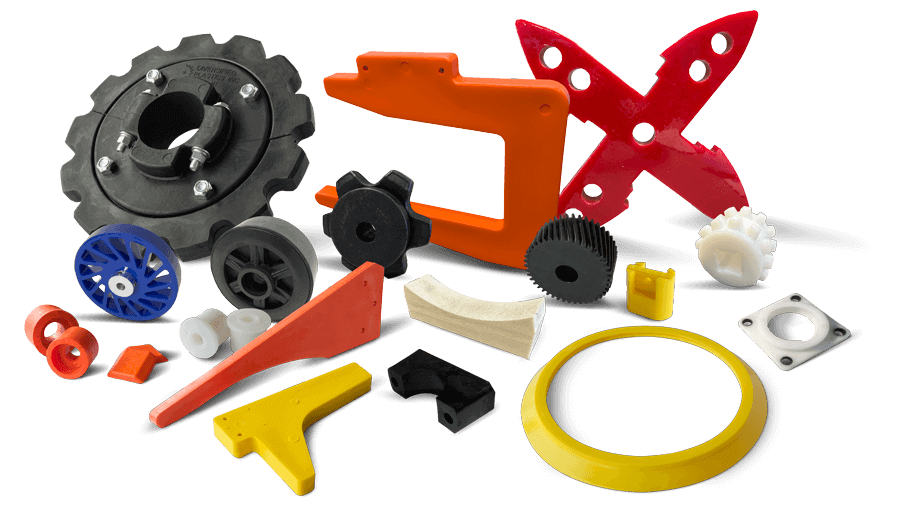

Engineered Plastic Components and Parts

- Sprockets & Gears

- Bearings & Bushings

- Pulleys & Belt Sheaves

- Diverter Arms/Guides

- Chain Guides, Tops, and Lugs

- Wheel Rolls & Rollers

- Augers

- Drive Components

- J-Hooks and Slider Blocks

- Impact Bumpers

What Plastic Components Are Used in Lumber Mill Equipment?

Our parts fit a variety of applications in the forest product industry from OEMs to end users. We can provide solutions from sorter system parts to urethane rolls to a variety of sprockets and gears.

We develop, engineer, and produce an extensive line of plastic components for lumber and timber processing equipment.

How to Choose the Right Plastic Material for Lumber Equipment Parts

The exact plastic material composition is an important factor when specifying parts for equipment used in the lumber and timber industry. Our plastic experts will determine the best plastic material, including custom resins and colors, for your application.

DPI’s UHMW (ultra high molecular weight) polyethylene is an excellent material choice for parts and components used in lumber and timber industry equipment applications that require superior durability, wear resistance, low friction, and corrosion resistance. Additionally, UHMW plastic can be machined, fabricated, or injection molded.

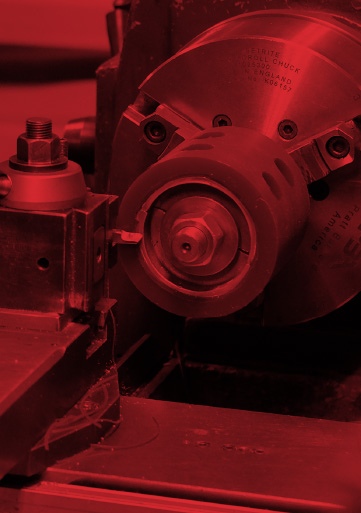

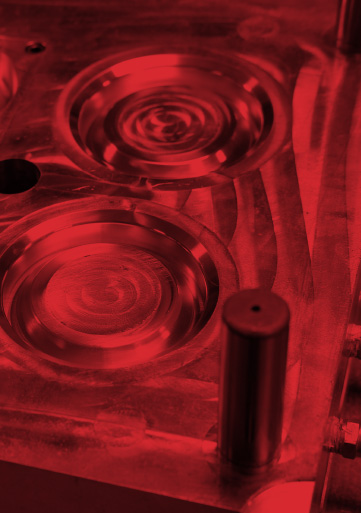

Diversified Plastics has mastered the art of injection molding Industrial Grade Polymers to meet custom designs and sizes. DPI is the only company with the capabilities to injection-mold UHMW polyethylene, thanks to our state-of-the-art facilities and plastics expertise.

Our proprietary injection molding process can produce products of:

- UHMW-PE

- High-density polyethylene

- Polypropylene

- Urethane

- Cast urethane

- Nylon

Our injection molding capabilities provide benefits such as custom and precision parts work, faster cycle times, reduced material waste, cost efficiencies, and high production runs.

For lumber mills, sawmills, pulp mills, and other timber producers, DPI’s engineered plastic and polymer products offer a range of important advantages over traditional materials:

Key Advantages of Plastic Components

- High Durability and Strength

- Cost Savings

- Self Lubricating

- Weight Reduction

- Corrosion Resistant

- Abrasion Resistance

- Noise Reduction

- Eliminates Hazards of Metal

- Excellent Alternative to Metal Parts

- OEM Replacement Parts

Why Choose Diversified Plastics for Lumber Equipment Parts

We know that lumber, forestry, logging, and pulp and paper processing work calls for durable, wear- and impact-resistant plastic components. No matter what your company requires, you can depend on Diversified Plastics OEM and replacement parts to keep up with your operation’s needs for the best value and lumber quality.

Diversified Plastics leads the industry with cost-effective and sound applications in the pulp and paper industry. With our many capabilities, we strive to dissolve problems that hinder production and efficiency. We know our customers’ need for reliable solutions and our plastic sprockets, when compared to traditional steel sprockets, provide the long-wear performance you need in production.

To keep your lumber equipment operating efficiently, consider DPI your best source for essential plastic parts to support your preventive maintenance program and replacement parts inventory. For emergency repairs or parts replacement, our team is standing by to provide the parts you need to minimize production downtime.

Contact DPI for Lumber and Timber Plastic Parts Expertise

From design to prototyping to process engineering, our team’s experience and expertise with the wide range of plastic solutions allows us to solve any plastic component challenge. Learn how we can put polymers to work for you!

Contact the sales experts at DPI to discuss your lumber equipment part needs, problem parts, weight reduction objectives, or custom part needs.

Call us today: 1-800-321-0084

The use of plastic is endless in the forest, timber, and paper industry. Call Diversified Plastics today to find out how we can improve your production.

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!