FOOD GRADE PLASTIC COMPONENTS FOR FOOD PROCESSING EQUIPMENT

Precision Plastic Parts for Food Processing, Packaging, and Conveying

Request a Quote1-800-321-0084

TRUSTED FOOD-SAFE PLASTIC COMPONENT SOLUTIONS FOR THE FOOD INDUSTRY

For over 50 years, Diversified Plastics Inc. has been serving the food processing, packing, production, conveying, and packaging industries with quality engineered, food-safe plastics.

The use of plastics in food processing and packaging machinery ensures smooth, efficient operations, minimizes wear and the potential for downtime, and outlasts and outperforms conventional equipment parts in challenging environments. In most applications, existing steel, aluminum, and other metal pieces can be easily replaced with today’s innovative, precision plastics.

Food Processing Equipment Applications

- Mixers & Agitators

- Conveyors & Compactors

- Mills, Presses & Screens

- Tanks & Centrifuges

- Dryers, Case Packers & Palletizers

- Cartoners, Wrappers & Metal Detectors

- Powder Fillers & Augers

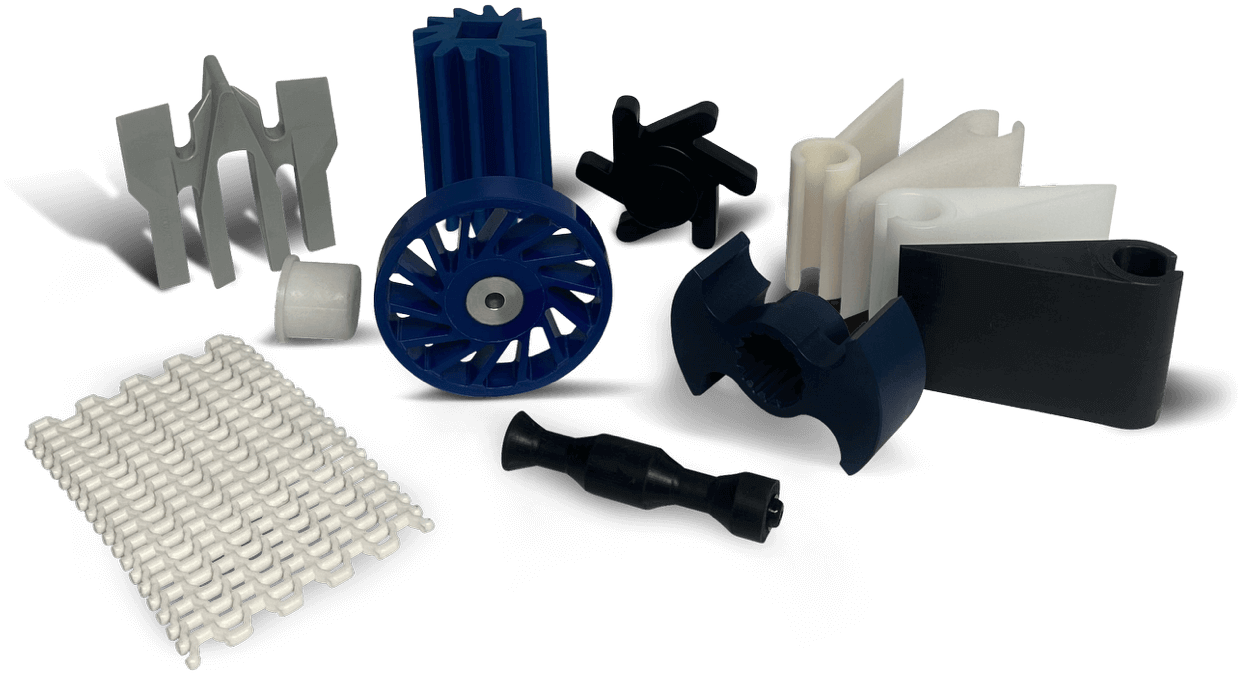

Engineered Food-Safe Plastic Components and Parts

- Scraper Blades & Wearstrips

- Sprockets & Chain Guides

- Gears, Bushings & Bearings

- Guides & Mixer Components

WHAT FOOD GRADE PLASTIC COMPONENTS ARE USED IN FOOD PROCESSING EQUIPMENT?

Today’s food industry relies on specialized machines that require specialized parts capable of withstanding repetitive motion, impact, and continuous operation.

As a single source for plastic parts engineering, tooling, and production, we can accommodate a range of project needs for meat products, frozen foods, fruit and vegetables, and pet food. Whether you require custom orders, short production runs, or high-volume quantities, our multiple manufacturing processes are designed to meet your specifications.

HOW TO CHOOSE THE RIGHT FOOD GRADE PLASTIC MATERIAL FOR FOOD PROCESSING EQUIPMENT PARTS

The exact plastic material composition is an important factor in the food processing industry. Our plastic experts will determine the best food-safe plastic material, including custom resins and colors, for your application.

Our precision plastic parts for food-safe applications are made of a variety of highly durable plastic materials such as food grade nylon, food grade acrylic, food grade HDPE, food grade UHMW, and FDA-approved elastomers. We continually innovate and look for ways to improve the equipment life and reduce long-term procurement and maintenance costs.

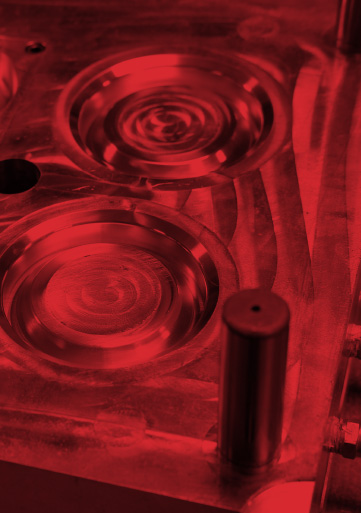

DPI’s food grade UHMW-PE (ultra-high molecular weight polyethylene) is an excellent material choice for food processing equipment components that require high durability, abrasion resistance, corrosion resistance, and low friction. Additionally, food grade UHMW-PE can be approved as FDA compliant and USDA compliant, ensuring it is suitable for food contact substances. We have the capabilities to injection-mold food grade UHMW to your exact part specifications.

Our creative engineering team specializes in designing innovative, custom food-grade plastic materials for food processing and packaging machinery, including the creation of metal detectable components that dramatically lower the risk of food contamination. Metal detectable plastics can provide superior wear properties with less noise, weight, and maintenance, all while meeting FDA requirements and ensuring food safety compliance.

For food processing operations, DPI’s engineered food-safe plastic and polymer products offer a range of important advantages over traditional materials.

- Wear Resistant

- Impact Resistant

- Abrasion Resistant

- Self Lubricating

- Weight Reduction

- Lower Noise Levels

- Reduced Maintenance

- FDA Compliant Options

- USDA Compliant Options

- Metal Detectable Options Available

- OEM Replacement Parts

WHY CHOOSE DIVERSIFIED PLASTICS FOR FOOD PROCESSING EQUIPMENT PARTS

We know that food processing, packaging, and conveying operations call for specialized, food-safe plastic components that can withstand continuous operation and repetitive impact. No matter what your company requires, you can depend on Diversified Plastics OEM and replacement parts to keep up with your operation’s needs for optimal long-term performance.

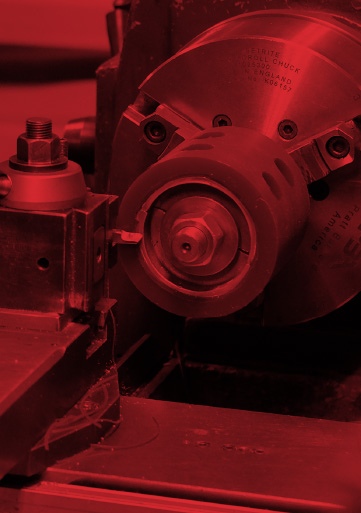

As a North American innovator and leader in the creative engineering, prototyping, machining, custom fabricating, thermoforming, and injection molding of industrial grade polymers, we’ll help you choose the best process to maximize your food processing and food packaging equipment investment.

We provide creative engineering, food-safe plastic components, and design solutions for custom-built food processing machines and OEM equipment applications. There are many opportunities to improve food processing production efficiency, quality, and safety with plastics.

CONTACT DPI FOR FOOD PROCESSING PLASTIC PARTS EXPERTISE

Whether you need design, prototyping, or process engineering, our team’s experience and expertise with the wide range of food-safe plastic solutions allows us to solve any plastic component challenge. Learn how we can put polymers to work for you!

Contact the sales experts at DPI to discuss your food processing equipment problem parts, weight reduction objectives, or custom part needs.

Call us today: 1-800-321-0084

Learn how Diversified Plastics can help improve your food business operations and discover why switching to food-grade plastic components is the right choice for your processing equipment.

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!