Career Opportunities

Work and live in beautiful Missoula, Montana! Diversified Plastics is a profitable, growing, privately held plastic manufacturer that has been in business over forty years. We are fortunate to have our business located in one of the most livable small cities in the United States. Proclaimed as the locale with the “best summer weather” in the United States by a prominent outdoor-oriented magazine, Missoula experiences warm summer days and cool nights. Outdoor activities are almost unlimited, including hiking, water sports, fishing, mountain biking, snow skiing, kayaking, and hunting to name just a few! Missoula is also home to the University of Montana.

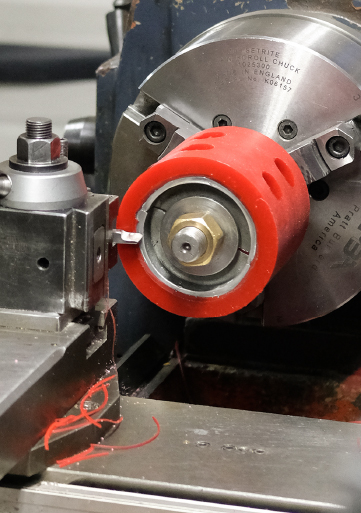

Diversified Plastics is continuously reviewing our staffing needs and hiring the most qualified personnel we can locate. Experience in the plastic industry is highly desirable for positions in the sales and production departments. The company offers a broad range of employee benefit programs as part of our commitment to our staff. We are especially interested in machinists who are experienced with CNC machines and injection molding equipment. We also operate a urethane casting operation and are interested in applicants with experience in this discipline. In some instances, we will consider recent trade school graduates for entry level positions if you have training on equipment we operate.

<a href="/employment-opportunities/employment-form/"><button class="redbutton" role="button">Apply Now</button></a>Current Positions Available:

Click on link below to apply today or fax us your information at 406-371-4964.

Department: Production

Reports To: Engineering Manager

Job Requirements and Experience

- Must be able to read engineering drawings

- Must have Manual Machining, CNC Programming and Machining, and Welding skills

- Must be able to build stamping dies, fixtures, and jigs as necessary for production

Job Hours and Availability

- Full time – 40 hours/week

- Day shift hours are Monday through Thursday 6:30 a.m.-4:30 p.m.

Essential Functions

- Stand for long periods of time

- Frequent movements of hands, wrists and arms

- Must be able to see objects less than a few feet in distance

- Lift up to 75 lbs.

Compensation and Benefits

- Pay starts at $22.00/hour, or more DOE

- 401(k)

- 401(k) matching

- Dental insurance

- Employer-Paid Health insurance

- Health Savings Account

- Lifestyle Spending Account

- Paid time off

- Parental leave

- Vision insurance

A leading manufacturer and distributor of plastic components offering a vast array of processes including injection molding, fabrication, and urethane casting is seeking an experienced CNC Machinist for the production area of their Missoula plant. Preferred qualifications 3 years of experience with CNC machining, both programming and operating, as well as, 3 years of Mastercam experience. 4th and 5th axis knowledge preferred. Must be mechanically inclined, detail-oriented, and capable of learning new processes. Need to have a safety conscience attitude, ability to follow direction, and ability to work well in a team environment. Day shift hours are Monday through Thursday 6:00 a.m. to 4:00 p.m. while swing shift hours are Monday through Thursday, 2:30 p.m. to 12:30 a.m., 40 hours/week. Pay starts at $22.00 to $26.00 per/hour, or more depending on experience, plus an excellent benefit package. The swing shift offers an additional $2.00/hr shift differential. Additional benefits include employer paid health insurance.

**Note company application is required in addition to submitting a resume.

** ESSENTIAL FUNCTIONS: Stand for long periods of time; frequent movements of hands, wrists and arms; see objects less than a few feet in distance; lift up to 75 lbs., twist, bend.

Job Type: Full-time

Salary: $46,760.00 – $72,000.00 per year

Benefits

- 401(k)

- 401(k) matching

- Dental insurance

- Employer-Paid Health insurance

- Health Savings Account

- Lifestyle Spending Account

- Paid time off

- Parental leave

- Vision insurance

Schedule

- 10 hour shift

- 4, 10’s

Experience

- CNC Machining: 1 year (Preferred)

A leading manufacturer and distributor of plastic components offering a vast array of processes including injection molding, fabrication, and urethane casting is seeking an injection mold technician for the production area of their Missoula plant. Experience not required but preferred. Must be mechanically inclined, detail-oriented, and capable of learning new processes. Need to have a safety conscience attitude, ability to follow direction, and ability to work well in a team environment. Probable hours of work will be Monday through Thursday, 2:30 p.m. to 12:30 a.m., 40 hours/week. Pay starts at $19.00/hour with a shift differential of $2.00/hour, or more depending on experience, plus excellent benefit package. Additional benefit includes employer paid health insurance.

** ESSENTIAL FUNCTIONS: Stand for long periods of time; frequent movements of hands, wrists and arms; see objects less than a few feet in distance; lift up to 50 lbs., twist, bend.

Job Type: Full-time

Salary: $39,520.00 – $68,000.00 per year

Benefits

- 401(k)

- 401(k) matching

- Dental insurance

- Employer-Paid Health insurance

- Health Savings Account

- Lifestyle Spending Account

- Paid time off

- Parental leave

- Vision insurance

Schedule

- 10 hour shift

- 4, 10’s

Experience

- Manufacturing: 1 year (Preferred)

Innovation is on the move. Join Us.

We are creative, engineering-minded problem solvers. And it shows. Diversified Plastics is a growing manufacturer of industrial plastic products located in Missoula, Montana. Our company is privately held and has been designing, fabricating, and molding plastic parts since 1976. Learn more about the benfits of working at DPI.

Download hereNeed Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!

Give Us A Call

1-800-321-0084

Outside the United States