Custom Fabrication

DPI Takes On Parts Design Challenges

And Answers Them With Viable Custom Solutions

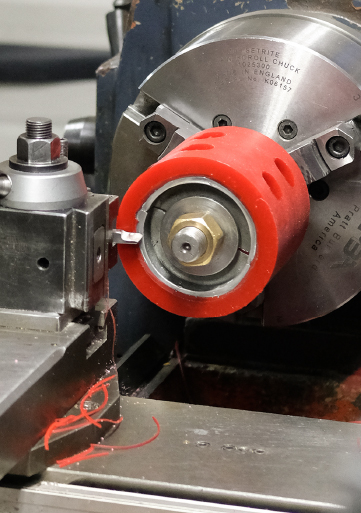

Diversified Plastics has the skills and equipment to employ a variety of fabrication processes for a variety of materials, from plastics to metals. This enables us to tackle projects that integrate disparate materials and take on complex forms. We can handle single assemblies as well as hundreds of units. Our experienced fabricators are cross-trained on all processes and work in the most advanced software interfaces for 3-D fabrication.

We employ a variety of advanced equipment and processes in fabricating. We use many specialized tools to complete our fabrication processes including saws, drill presses, router, hydraulic presses, and more.

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!

Give Us A Call

1-800-321-0084

Outside the United States