Overmolding Services & Insert Molding

DPI Overmolding & Insert Molding Deliver Durable Grip, UHMW-Level Wear Resistance, Metal-Strength Threads and Bearings, and Simplified Assembly

When one material alone can’t meet all your performance needs, DPI combines them intelligently. Our Overmolding process layers a second, usually softer plastic over a rigid substrate, giving you enhanced grip, impact absorption, and wear properties. Meanwhile, our overmolding approach encases metal components — threads, shafts, bearings — in plastic, concentrating strength and wear exactly where it’s needed. The result? A single, integrated part with superior grip, exceptional durability, and cost-effective design.

Overmolding Advantages

- Targeted performance where it counts: grip, wear, impact damping

- Localized metal strength with insert-molded threads, shafts, bearings

- Fewer fasteners/adhesives; simpler assemblies

- Cost reduction by keeping only critical features in metal

- Consistent quality through DFM guidance and repeatable bonding methods

We’re redefining plastic performance

Talk with one of our engineers about optimal material pairings, bond strength, and DFM strategies.

Call us at 1-800-321-0084 to get started or to request a quote.

Common Applications & Use Cases

- Soft, high-traction layers over hard substrates — high-grip rubber/TPE over high wear UHMW wheels

- Impact protection — soft urethane over steel shafts

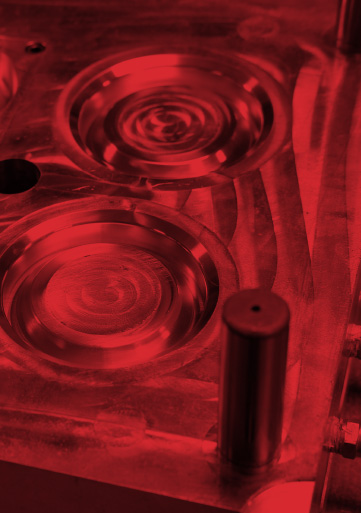

- Wear + strength combos — UHMW over glass-filled PP, joined to a glass-filled nylon bore with keyway for high-torque drives

- Cost-optimized threaded parts — plastic housings with insert-molded steel inserts that deliver the strength of steel where you need it while capturing the savings of lower-cost plastics.

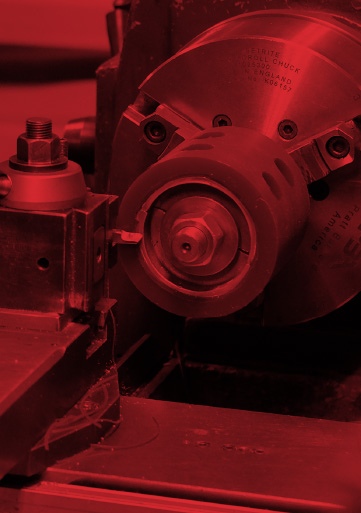

- Low-friction rollers — UHMW, nylon, or acetal bodies overmolded around steel ball bearings for wheels and sheaves

What Is Overmolding? (Overmolding vs. Insert Molding)

Overmolding bonds two compatible plastics into a single part—ideal for adding grip or a durable wear surface to a rigid substrate.

Insert molding encapsulates pre-placed components—commonly steel or brass threads, bearings, or shafts—so you achieve metal strength only where required while keeping the rest of the part lightweight and economical.

Overmolding is often treated as a subtype of insert molding; it may require multiple shots or more complex tooling, which we’ll weigh during DFM to balance cost and lead time.

Materials & Design for Overmolding

We regularly run UHMW, TPE/TPU, nylon (PA), polypropylene (including glass-filled grades), cast urethanes, and acetal. Typical inserts include steel, stainless, brass, bearings, and shafts. For reliable bonds, we match resin chemistry and—on engineering resins like nylon or PC/ABS—specify adhesion-modified overmold grades when appropriate.

To ensure reliable bonding, our engineers:

- Recommend ideal resin pairings or adhesion-enhanced overmold grades (especially for engineering resins like nylon or PC/ABS).

- Use mechanical interlocks or undercuts where needed for strength.

- Maintain uniform wall thickness (for example, many TPE overmold layers perform well at about 1.5–3.0 mm)

- Highlight problematic geometries that could weaken bond strength or lengthen the molding cycle.

Dual-Durometer & Overmolding FAQs

For TPE overmolds, we typically aim for ~1.5–3.0 mm (≈ 0.060–0.120 in). We avoid large jumps in thickness and encourage gradual transitions to optimize part strength and cycle time.

Yes — we can source steel, stainless, brass inserts, bearings, or shafts, or mold around components you provide.

Absolutely. In our DFM review, we evaluate resin chemistry, wall uniformity, gate/cooling design, and interlock features to maximize adhesion.

Contact & Next Steps

Let’s talk about how DPI can solve your design challenges.

Call: 1-800-321-0084

Or: Contact a sales rep to request a quote or a design discussion

Need Support?

When you know what you are looking for or want to start with an idea, we are ready to help. Please reach out and we will start you on your path to plastic solution success!